Products > Accessories > Motomag Wheels

Motomag Wheels

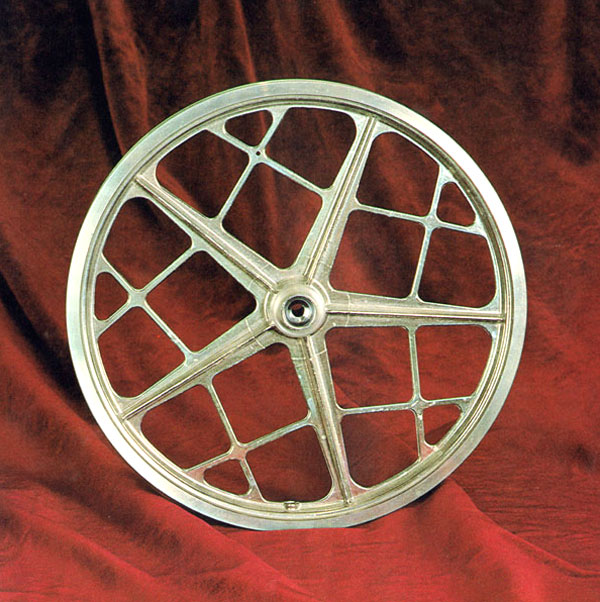

The original, largest selling, best looking aluminum “Mag” type wheels on the market. Lighter, stronger with new polished finished.

Motomag I- are made out of 356 aluminum alloy. They are of a gravity, centrifugal, permanent mold cast, heat treated to T-6 condition, shot peened for the rough finish, rim edges and tire beads machined, center bore machined for either front or rear wheel specifications, front axle cups installed for front wheels, coaster brakes press fit for rear wheels. These wheels were slow and difficult to cast.

Motomag II -are made out of 380 aluminum alloy. High pressure die cast, tumble polished, rim edges and tire beads CNC machined, center bore CNC machined for either front or rear wheel specifications, front axle cartridges press fit for front wheels, coaster brakes press fit for rear wheels. These wheels were manufactured with high production rates and little rejects. Motomag II wheels were first available in the "classic" ball burnished finish, then became available in colors starting with pinapple gold / Root beer brown (on JAG) in 1978 and gold in 1981 (on mongoose), then other colors were added onwards which included Black, White, Yellow, Red, Candy Red, Blue, Candy Blue, Gold, Candy Gold (pineapple gold) and Root Beer Brown.. Motomag II wheels continued up until sometime in 1984, when lighter spoked wheels and optional "mongoose stamped" Skyway Tuff wheel II were offered as an option.

According to Skip “Motomag Wheels were sold to bicycle wholesale distributors world wide. Companies like, Huffy, Murray, Schwinn, Raleigh, Jag Bicycles and many others.

Below are excerpts of interviews done with Skip Hess.

November, 2007

Where did you work when you came up with the idea for the first

Motomag wheel?

At the time I was a design consultant, working at home, for many, many car wheel companies. I provided cast aluminum wheel designs, mold design drawings and machining drawings. Boys in my neighborhood were riding and jumping bikes and I was rebuilding bike wheels regularly. I believed that a cast aluminum bicycle wheel would be stronger and more reliable than a conventional spoked wheel. I solicited the design to my car wheel customers, but they were not in the bicycle trade and were no interested in it. I then proceeded to manufacture Motomags on my own, which initiated my company.

What were your inspirations for the designs?

My extensive car wheel designs led to the Motomag design. The small beauty spokes were to provide safety for hands and/or feet.Who produced the Motomag Wheels for BMX Products, Inc.?

Cragar was the only foundry for these permanent mold castings. The molds were the property of BMX Products, Inc.

How much were the molds for the Motomag?

Motomag II - molds were very complex and we made three of them to keep up with huge sales. The cost was about $65,000 each.How did you go about getting the molds made for the Motomag?

All molds were made by local die shops that I knew from the car wheel business.

Do you know where the molds for the old Motomag exist today?

They were sold for scrap as they were well worn. We produced hundreds of thousand of aftermarket wheels that were also sold to Huffy, Murray, Raleigh, Jag Bicycles, and Schwinn and many others. The Motomags were also OEM on several other bike brands. We also exported them to many foreign markets.

Were there any non production Motomags out there that were made of Magnesium? There is the rumor that there were a few sets made out of a special material only for Rick Twomey and others?

I made a handful of magnesium Motomag Ones for Rick Twomey’s Mongoose BMX team to use in high profile races. They were extremely light weight. I found a foundry to make a few sets and mag is very dangerous, so they made them at night to avoid penalty for not having the proper license. The mags were really much lighter, but cost prohibitive. We made a wooden form so as to sand cast the mag. The real concern was machining as mag chips and dust will catch fire. This was a team secret at the time. Twomey’s team carried the name of “Rick’s Bike Shop”, but he never had a bike shop. He did have the most experienced and fastest riders in this early era of BMX racing. He later was employed by me.

Side-by-side comparison of the 3 versions of Motomags

(Magnesium Motomag I, Alloy Motomag I, Alloy Motomag II)

Quote; "There were actually 2 versions of the Motomag Ones. The original was made in Simi and was marked "patent pending".

The centrifugal cast Motomag Ones were hard on the molds and I made additional molds, not versions, for attrition. As previously noted, Simi was my office location, not the place of manufacture.

Quote; “Production was then moved sometime in 1976 to Chatsworth, the Motomag Ones that were produced there were marked "US PAT ####### “.

Again, the molds had to be replaced due to wear. Later molds, not versions, incorporated the US Patent number when it was issued. We produced a monumental quantity of Motomags.

Quote; “Both wheel sets share the no valve stem collar, and no center rib characteristic of the Motomag Ones. They were then replaced by the Motomag II in early '77. True, bit I am not sure of the exact dates.

Regards

Skip